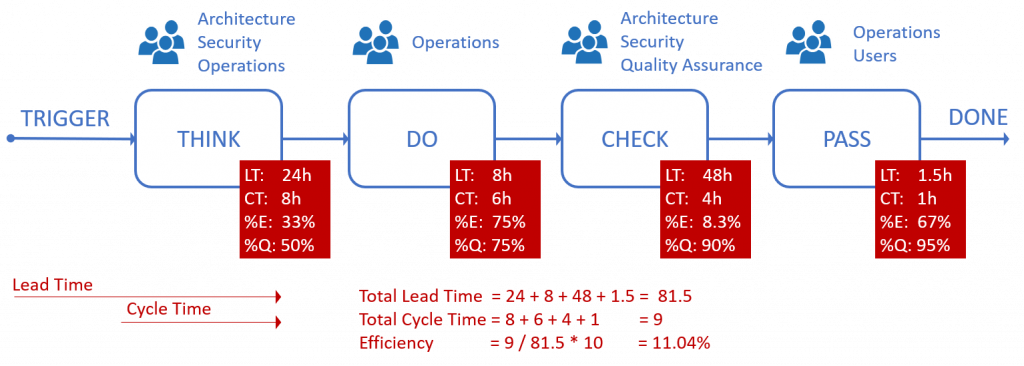

We all have value streams. Some are simple, some are complex, and some are organised around the flow of value. We map our value steams to understand and visualise the process, and to identify where problems disrupt the flow of value.

In this simplified walk-through, we use a three-step value stream mapping to visualise your process, such as your continuous delivery pipeline, and highlight bottlenecks and waste with actionable metrics.

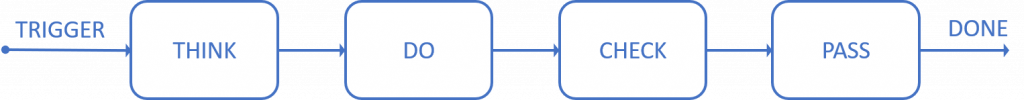

Step 1 – Visualise all activities

Map all the activities from ideation to deprecation. No activity or step is too trivial to be part of your value stream map!

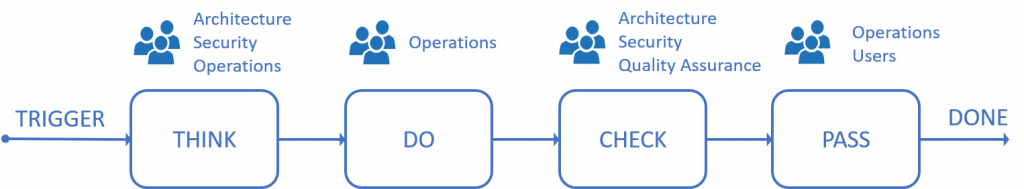

Step 2 – Identify stakeholders

Next, show all the stakeholders, who are directly involved in each activity of your process. It is important that we understand who is involved and accountable for the work performed!

Step 3 – Measure, measure, measure!

To uncover bottlenecks, waste, and problems, originating from upstream activities, you need to calculate and visualise value stream measurements.

The lead-time is the time an activity is ready to be worked on to its completion. Think of it as the time from when you place an order at a restaurant to when the meal is served. When you must wait a long time (long lead-time), you are not delighted!

The cycle time is the valuable time spent doing the actual work to complete the activity. This is like the time it takes the kitchen to cook your meal.

The efficiency percentage is a ratio of an activity cycle and lead time. Low efficiency percentages signify an opportunity to remove waste and bottlenecks.

Lastly, the quality percentage signals how well we are handling quality at each activity. The higher the %, the less rework (waste) is needed to move through our process.

| Look for activities: – With low efficiency – CT/LT*100 – With long lead times, those with short cycle times Question: Why are we waiting to get the work done? – With poor efficiency percentages Question: Why do we need to rework activities? |

| METRIC | NOTE |

|---|---|

| Lead Time (LT) | Time from earlier activity to end of current activity |

| Cycle Time (CT) | Time to complete the activity |

| %Efficiency (%E) | CT/LT – Effectiveness |

| %Quality (%Q) | % of earlier activities with no rework |

| Total LT | TLT – Sum of all lead times |

| Total CT | TCT – Sum of all cycle time |

| Total %E | TCT/TLT – Overall effectiveness |

| “I recommend that you hang a copy of your value stream mapping diagram in high-traffic and high-visibility areas. That allows your team and other stakeholders to review and discuss the learnings and add their unsolicited feedback. For example, your team’s breakout area, cafeteria, or outside the restrooms.” |